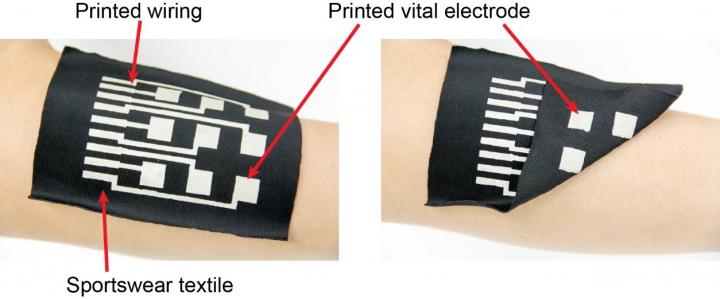

Researchers at the University of Tokyo have created a single-step

process to print conductive material on cloth, allowing manufacturers to

build stretchable wearables that can test vital signs like heart rate

and muscle contraction.

Researchers at the University of Tokyo have created a single-step

process to print conductive material on cloth, allowing manufacturers to

build stretchable wearables that can test vital signs like heart rate

and muscle contraction.From the release:

Now,

Professor Takao Someya’s research group at the University of Tokyo’s

Graduate School of Engineering has developed an elastic conducting ink

that is easily printed on textiles and patterned in a single printing

step. This ink is comprised of silver flakes, organic solvent, fluorine

rubber and fluorine surfactant. The ink exhibited high conductivity even

when it was stretched to more than three times its original length,

which marks the highest value reported for stretchable conductors that

can be extended to more than two and a half times their original length.

Why is this important? Because it allows for the traces to and from

electronic components to be amazingly stretchy. While components like

chips and transistors are still hard to pull and bend, by allowing the

connectors to bend and stretch in certain places you can create a

tighter fit for measurement technologies and even bring connectors up

close to your skin. The technology isn’t quite ready for prime time but

it should be an interesting addition to the wearables world when it’s

commercialized.